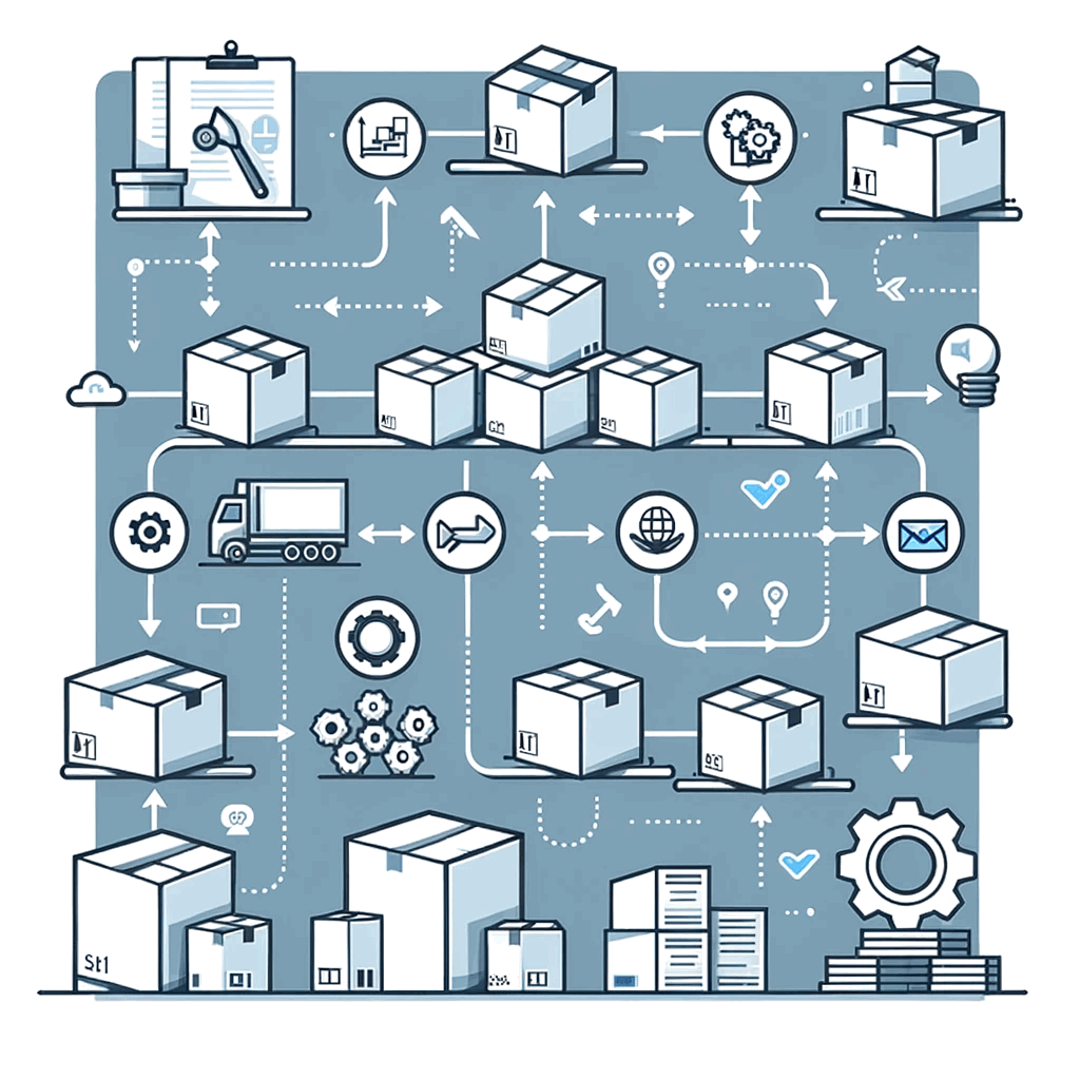

Materials management process: a clear and simple overview

What is materials management?

In a world where we possess always more, it gets harder to find clarity with all the materials we own. This fog will reduce your productivity. In your personal life, this can be translated into a messy desktop, bad habits, unclear thoughts, and so on. In your professional life, this can lead into bad choices, arguments with colleagues, and more.

SAP - no matter how short it is, but the essence is the same - it is an automated system that offers a set of solutions for building a common information space based on an enterprise and effective planning of resources and workflows. Its tools can be used both individually and in combination.

SAP ERP material management is the best way to improve your business performance and increase your income.That is why materials management is now a core supply chain function in every enterprise and is part of all ERP solutions available on the market. Basically, raw materials management is the capability firms are using to plan total material requirements.

Plan is the keyword. The process behind materials management is scheduling. The goal of the process is to be ahead to see the issues coming. Being ahead will provide an unbroken chain of components for production to manufacture goods on time for customers delivery.

How to master your materials

The biggest ERP implementation challenges related to masterong your materials is the consistent flow of materials for production. Indeed, the flow is never-ending, and you must control it. The best tool for this is using production management software, such as SAP. The Gantt diagram tool inside it will help you to track the product and the materials. In order to use it properly and manage your materials, here is the process in 3 steps:

Step one: start at the end

Start at the end. Begin your work by checking the date the customer’s order must be shipped.

Step two: Check the production chain of the product

Imagine and write down all the process to create the product, using the same way as if you want to know at what time to leave your home to not miss your flight. By doing this, you will arrive to a date. This date corresponds to the moment where you have all your materials stored in the store.

Step three: 3. Check your providers delays

With those delays needed to order these products to your providers, you will finally arrive to the dates that you need to do your providers orders. This is the most important date. If you are late with this date, you may get late after, or create inconsistencies in your production.

The production chain

What you just did is going through all the production chain. Now, you can put it into a Gantt diagram. You can be on paper or on a software. The latter option is the best because there are some automatic tools to adapt the diagram automatically. Excel has a built-in tool, just like SAP or Prelude. We encourage you to check further information about those ERP tools.

The operational procurement process

As you just saw, managing your materials is key to have a constant flow of production. In order to do that, you should examine your supply chain in detail, especially the production chain of the production that interests you.

Then, look at the customer’s deadline, get your manufacturing programs with all the materials needed and the number of each part to create one final product. Once you have them all, consider the time each task lasts. Write down the dates considering your machines availabilities.

Those dates or the moments you should have the pieces in your store. Take some margins (not too much) and order the products at the right date. Once this is done, you should have a good start to have a constant materials flow.

There could still be some issues, but maybe they come from other parts of the supply chain. Maybe you have a strong bottleneck in the production line, or some recurrent breakdowns on specific machines.

The best way to implement all best practices regarding materials management is to get SAP training online for all collaborators that are gonna work on the operational procurement processes, for example starting with a SAP Materials Management online course.

Frequently Asked Questions

- What are the key elements and benefits of an efficient materials management process in ERP?

- Key elements of an efficient materials management process include inventory control, procurement planning, and supplier management. The benefits include reduced costs, improved inventory accuracy, and enhanced supplier relationships, leading to overall operational efficiency.